It was very nice experience of attending the CAD training session at your Institute. I want to thank you & the faculty for providing excellent training with classroom lectures & necessary hands on examples

S. Raja,

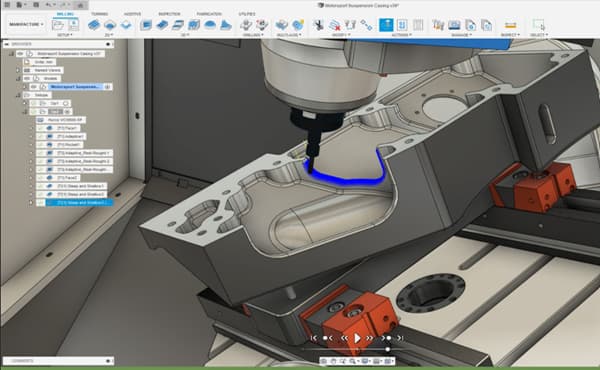

CoimbatoreEasy to use tool path creation interface for all the real time controllers like Fanuc, Siemens, Mitsubishi, Haas controllers and many more for up to 3 axis milling, Turning, 3+2 axis strategies ( Mill + turn ) and finally it’s a cloud platform which enables users to access their designs and projects anywhere at any time.

A fully integrated manufacturing workspace connects design and engineering to your manufacturing process.

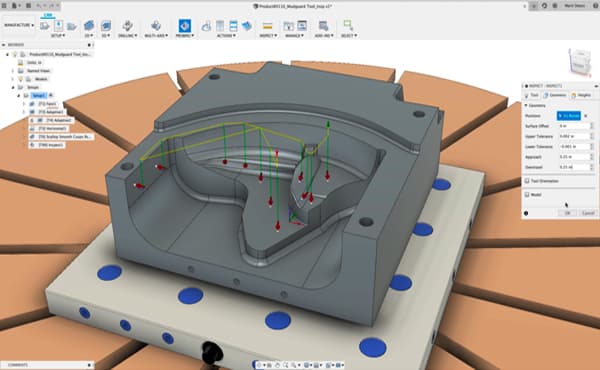

Programme complex, feature-rich components with ease using intelligent whole-part strategies like steep & shallow, deburr, hole recognition, and rotary.

Use CAD-based probing and spindle mounted probes to measure and improve the accuracy of your CNC machining. Intelligent part alignment helps save time and produce better quality parts.

Save time and money with spindle-mounted touch probes for CNC machining. Measure stock material, update work offsets, monitor quality, automate part setup, and more.

Speed up CAM programming with powerful modification tools that can turn a good toolpath into a great one – all without wasteful recalculation time.

Achieve superior surface finish with specialised 4- and 5-axis toolpaths. Additional axis controls and collision avoidance ensure safe, smooth machine motion.

Access advanced tools for complex CNC machining, sheet nesting and additive technologies to increase your manufacturing capabilities.

Combine milling and turning operations together to generate NC code that can help you produce more complex parts using multi-tasking hardware capable of supporting both styles of machining.

The Fusion Manufacturing Extension enables manufacturers to create multiple-sheet nests from a design. These optimize material yield and minimize waste from flat raw material cutting operations.

Capabilities include:

Here are few samples of creative projects made by our students