I had training for AutoCad at this place. The tutoring at this place, i would say, was very professional. The facilities were good. All of this at a very reasonable price. So on the whole a good experience.

Ashwath, Student

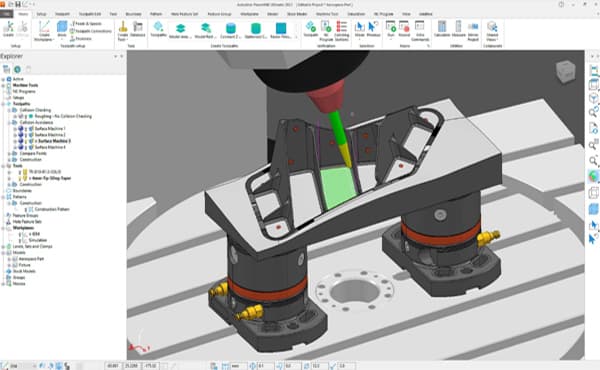

CoimbatoreAutodesk PowerMill CAM software provides expert CNC programming strategies for complex 3- and 5-axis manufacturing, Enjoy a vast library of machining strategies.

Complete control of the machining process helps you achieve optimum levels of precision and surface finish.

Super-fast toolpath calculation makes it simple to program large moulds, tools and dies, and other challenging 3D geometry.

Advanced controls help optimise NC code to extract maximum value from your machines and cutting tools.

PowerMill provides a vast library of 3- and 5-axis strategies that simplify the CAM programming and CNC machining of large moulds, tools, dies and other complex parts.

Advanced toolpath controls and powerful editing shortens CAM programming times and increases flexibility, resulting in finished parts that require little to no manual polishing.

Powerful templates and user-defined macros help you capture and share best practices across your team. Address the skills gap and help your workers to be more productive sooner.

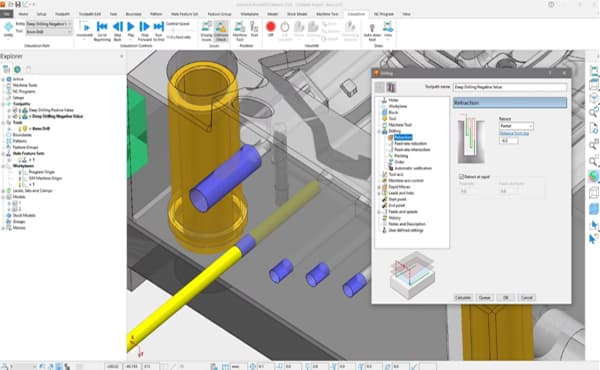

Import surfaces, solids or meshes from mainstream CAD systems and produce NC code even if data is poor quality

Choose from a range of roughing strategies to remove material quickly and maximise cutter life

Access a library of finishing toolpaths to produce precision parts with exceptional surface finish

Simplify 3+2 and 5-axis machining to produce parts with fewer setups, shorter tools, and faster feeds and speeds

Make global or localised edits to your toolpaths without the need for lengthy, wasteful recalculations

Check individual toolpaths or entire projects to find and fix problems before they cause expensive mistakes

Use a 3D model of your CNC machine to simulate toolpaths and identify collisions, near-misses or over-travel

Use configurable post-processor files to export safe and efficient NC code to suit your specific machine

Embed your best practices into templates and macros and share with others to automate common tasks

Create, control and simulate deposition strategies for driving high-rate additive processes such as DED and FFF

Offline programming and simulation of industrial robots with analysis to avoid singularities and over-travel

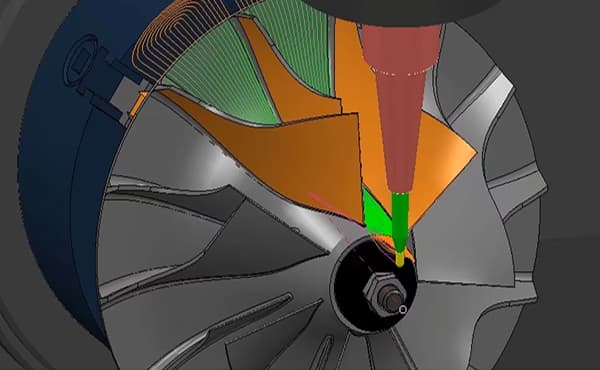

Access specialised strategies to manufacture ports, manifolds, blades, blisks and impellers

Here are few samples of creative projects made by our students